The mining industry, while vital to the global economy, faces significant challenges in terms of sustainability and reducing greenhouse gas (GHG) emissions. Among the many environmental issues underground operations encounter, air heating and ventilation are strategic priorities. Recognizing this, Glacies Technologies has developed a revolutionary solution leveraging energy stored in water to reduce GHG emissions and operational costs while enhancing air quality.

This article delves into a collaborative project initiated in partnership with Groupe MISA, which aims to assess the technical and economic feasibility of this groundbreaking technology in the mining sector.

In underground mines, operations and the use of motorized equipment generate dust and pollutants. Ventilation systems are crucial for maintaining air quality that complies with safety standards, ensuring fresh air for workers.

However, during winter, the air introduced into the mine must be heated to prevent the ventilation shaft from freezing and other issues that could halt mining operations. Currently, this process largely relies on direct combustion heating methods (propane and natural gas) or indirect methods (diesel).

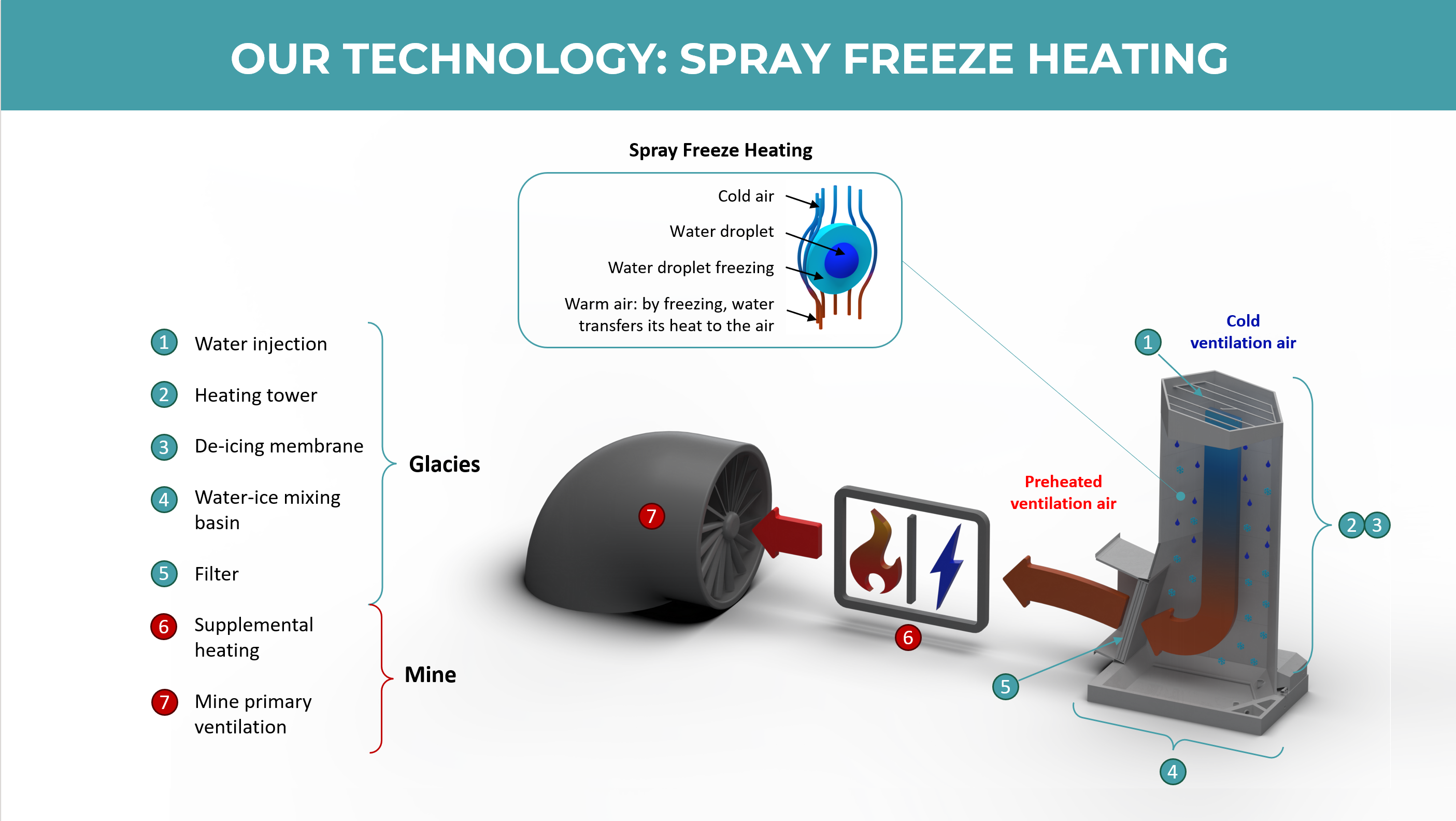

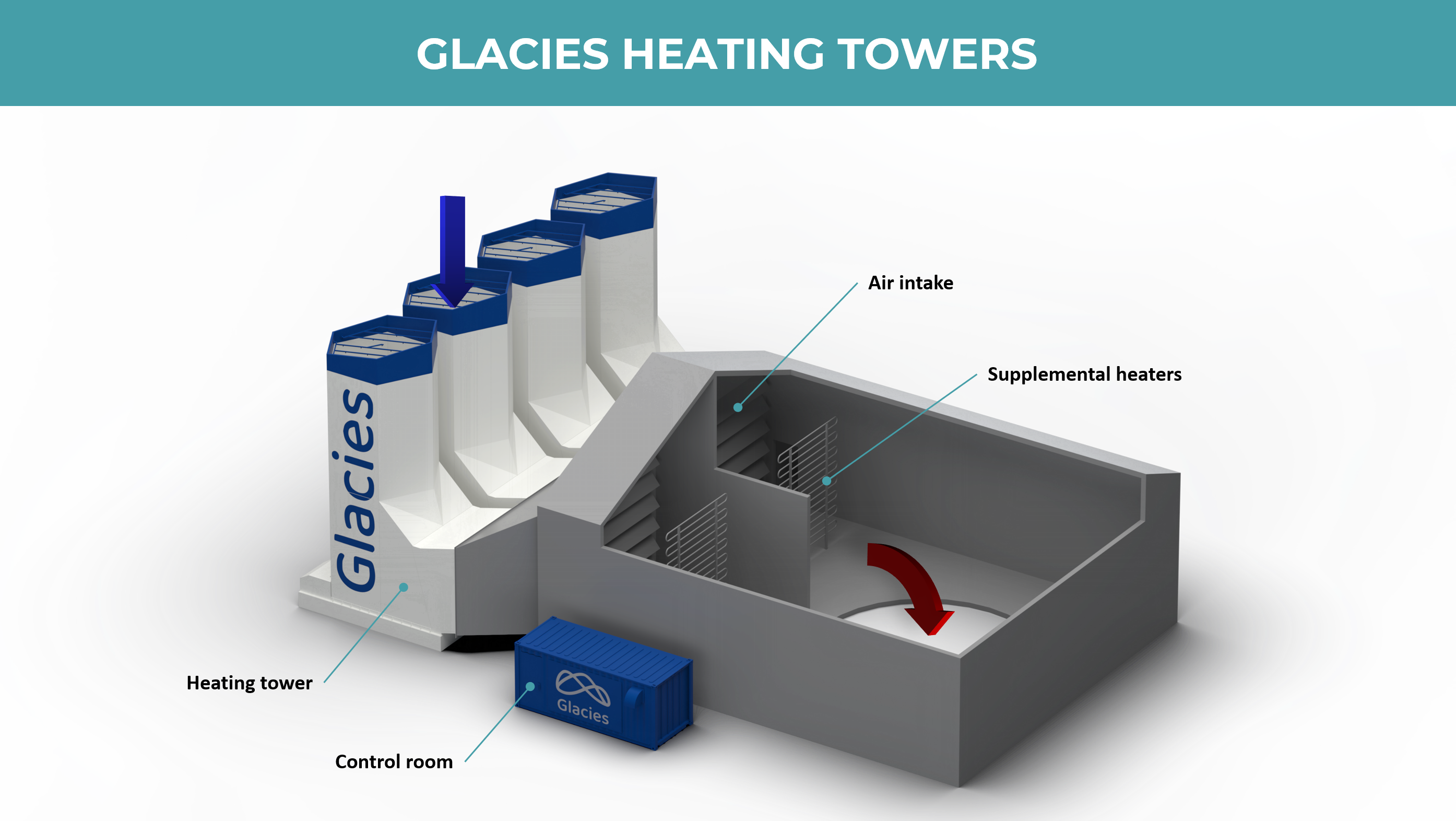

Glacies Technologies is developing a unique technology that harnesses the phase-change energy of water stored in mining site settling ponds to preheat air for underground operations.

In partnership with Groupe MISA, Glacies Technologies has launched a techno-economic study to determine the parameters for implementing this technology in mines.

This study will establish optimal deployment scenarios for this technology, fostering its adoption across the industry.

Energy consumption for heating and ventilation is a substantial portion of mining operational costs. By optimizing these processes, Glacies Technologies’ solution offers benefits on multiple levels:

As the mining industry strives to reduce its ecological footprint, solutions like Glacies Technologies’ innovation are essential for meeting stakeholder expectations.

The results of this study could pave the way for wider adoption of this technology, positioning Glacies as a leader in energy innovation for the mining sector.

This project underscores the importance of collaboration among technology experts, research institutions, and mining companies to overcome sustainability challenges.

Glacies Technologies’ initiative demonstrates how innovation can transform traditional practices into sustainable, efficient solutions. By addressing one of the main sources of GHG emissions in underground mines, this technology presents a unique opportunity to reduce environmental impact while increasing profitability.

Through this initiative, the mining industry could become a model for integrating clean technologies, contributing to global GHG reduction goals. The future of underground heating begins here, with solutions that respect both the environment and the operational demands of mines.

– Until February 20, Corem and…

A reflection presented by MISA…