From fleets of automated vehicles to smart sensors and remote control systems, connected technologies are now at the heart of mining operations. But this connectivity relies on two essential conditions: network reliability and wireless performance.

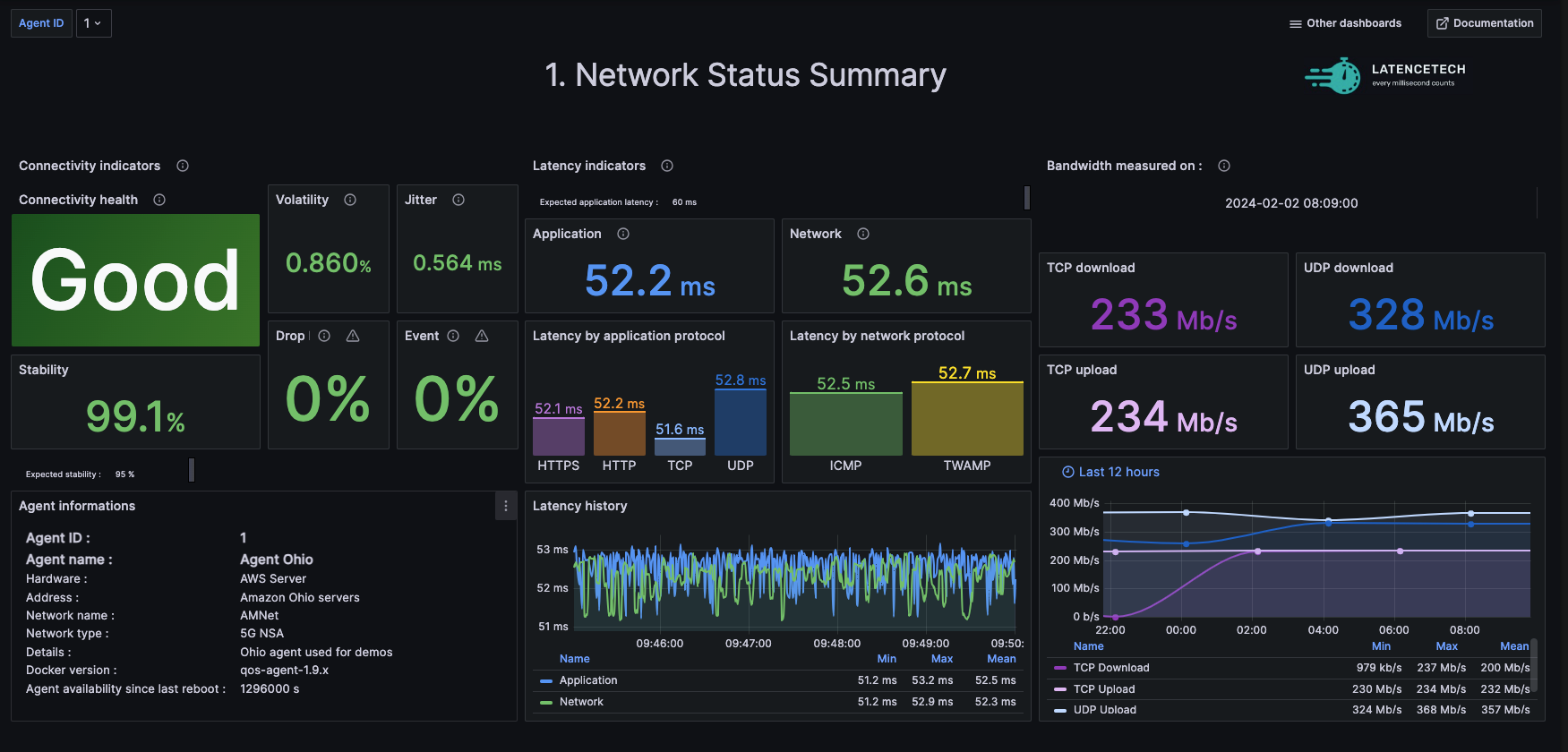

This critical need is precisely what LatenceTech’s innovative project addresses. Based in Montréal, this telecommunications and artificial intelligence company has developed a software solution to measure, analyze, and predict, in real time, the quality of wireless networks deployed in mines, integrating layers of algorithmic intelligence tailored to the most complex environments.

LatenceTech is rapidly growing in the communications technology sector. With deep expertise in latency issues, the company develops solutions that help businesses better understand, monitor, and anticipate network behaviour.

Headquartered in Montréal, but active across several regions in Canada and internationally, LatenceTech stands out for its ability to turn network data into decision-making intelligence—especially in demanding sectors such as mining.

With the rise of sensors, connected equipment, and automation in mining, wireless network performance has become essential for worker safety, operational productivity, and asset maintenance.

Even with the deployment of robust private networks (Wi-Fi, LTE, 4G, 5G), mine operators still face several challenges:

Variability of underground coverage

Proliferation of connection points

Management of multiple parallel networks

Limited visibility into the actual signal quality perceived by equipment

Difficulty diagnosing network incidents and outages quickly

LatenceTech offers a unique software solution to close these gaps.

The project aims to design a software platform for monitoring and predicting wireless network quality, specifically adapted to the mining sector.

Four key functions stand out:

Real-time measurement of network performance from the perspective of connected devices (IoT, machines, sensors, etc.)

Anomaly detection using artificial intelligence and complex data processing

Prediction of upcoming degradations to enable proactive interventions and prevent outages

On-demand diagnostics of network quality and performance

This approach maximizes network availability, improves the user experience of connected systems, and strengthens the resilience of digital mining operations.

As part of the Vortex Journey, the project’s first phase will be carried out in partnership with mining equipment suppliers. This strategy integrates the software platform directly into the suppliers’ systems to:

Guarantee higher connectivity quality

Optimize connected equipment performance on-site

Facilitate interpretation of real-time transmitted data

Maintain expected network quality levels for mining operations

These initial deployments will also allow LatenceTech to validate its solution in real industrial contexts while strengthening its value proposition to mining operators.

The project will unfold over 14 months, in several complementary phases:

Logistical preparation: coordinating with partners to identify targeted equipment and technical requirements

Software design and development: adapting the platform to mining environments and constraints

Controlled environment testing: initial technical validation with equipment suppliers

Real-world mine testing: data collection in operational settings

Results analysis: refining algorithms based on use cases

Commercialization strategy: finalized in collaboration with 48e Nord

The total project budget is $737,145. Nearly 80% of costs are dedicated to LatenceTech’s development team, which will lead:

Software design

AI module programming

Testing and validation activities

Data analysis from mining sites

A portion of the budget is also allocated to technical travel and coordination with equipment suppliers and subcontractors, whose in-kind contributions are essential to the solution’s relevance.

For years, mining companies have invested in connected technologies to:

Improve worker safety

Optimize equipment usage

Reduce unplanned downtime

Centralize operations in advanced control centres

However, this increased dependence on networks makes reliability critical. Many sites still suffer from dead zones, variability, latency issues that are difficult to identify, and delays in obtaining accurate quality and performance data.

Currently, few solutions monitor these networks from the equipment’s perspective, and even fewer can predict their behaviour. LatenceTech’s project fills this important gap in the digital mining ecosystem.

LatenceTech’s project fits perfectly with Groupe MISA’s mission to drive the adoption of smart technologies in Québec’s mining sector.

Through its innovative approach, technical rigour, and active partnership with equipment suppliers, the project:

Strengthens operational safety

Improves communication system reliability

Supports mining operators’ digital transformation efforts

Contributes to the development of Québec-made solutions exportable worldwide

In a sector where every second of network uptime counts, the ability to anticipate failures becomes a decisive competitive advantage. With its intelligent platform for measuring, analyzing, and predicting wireless network quality, LatenceTech puts connectivity at the core of mining performance.

This project demonstrates how artificial intelligence—when well integrated into operational realities—can reduce risks, increase productivity, and improve safety, while enhancing the overall efficiency of the mining industry’s digital infrastructure.

A reflection presented by MISA…