As the mining industry continues to modernize—where efficiency, safety, and profitability increasingly rely on automation and real-time data—intelligent equipment monitoring has become essential. Linersense Inc., founded in April 2024 following a partnership between Labcan and Techno Vogue (TVI), addresses this need with SAGSENSE-UT®, an innovative wireless technology designed to monitor wear in SAG grinding circuits.

Grinding circuits, particularly those using semi-autogenous grinding (SAG) mills, are among the most heavily stressed components in the mining value chain. The internal liners of these mills are subjected to constant impacts, friction, and variable loads. Excessive or undetected wear can lead to:

Cracking or deformation

Material leakage

Unplanned shutdowns

Increased safety risks

Today, liner monitoring often relies on manual inspections or indirect estimates, limiting operators’ ability to anticipate failures and plan maintenance effectively.

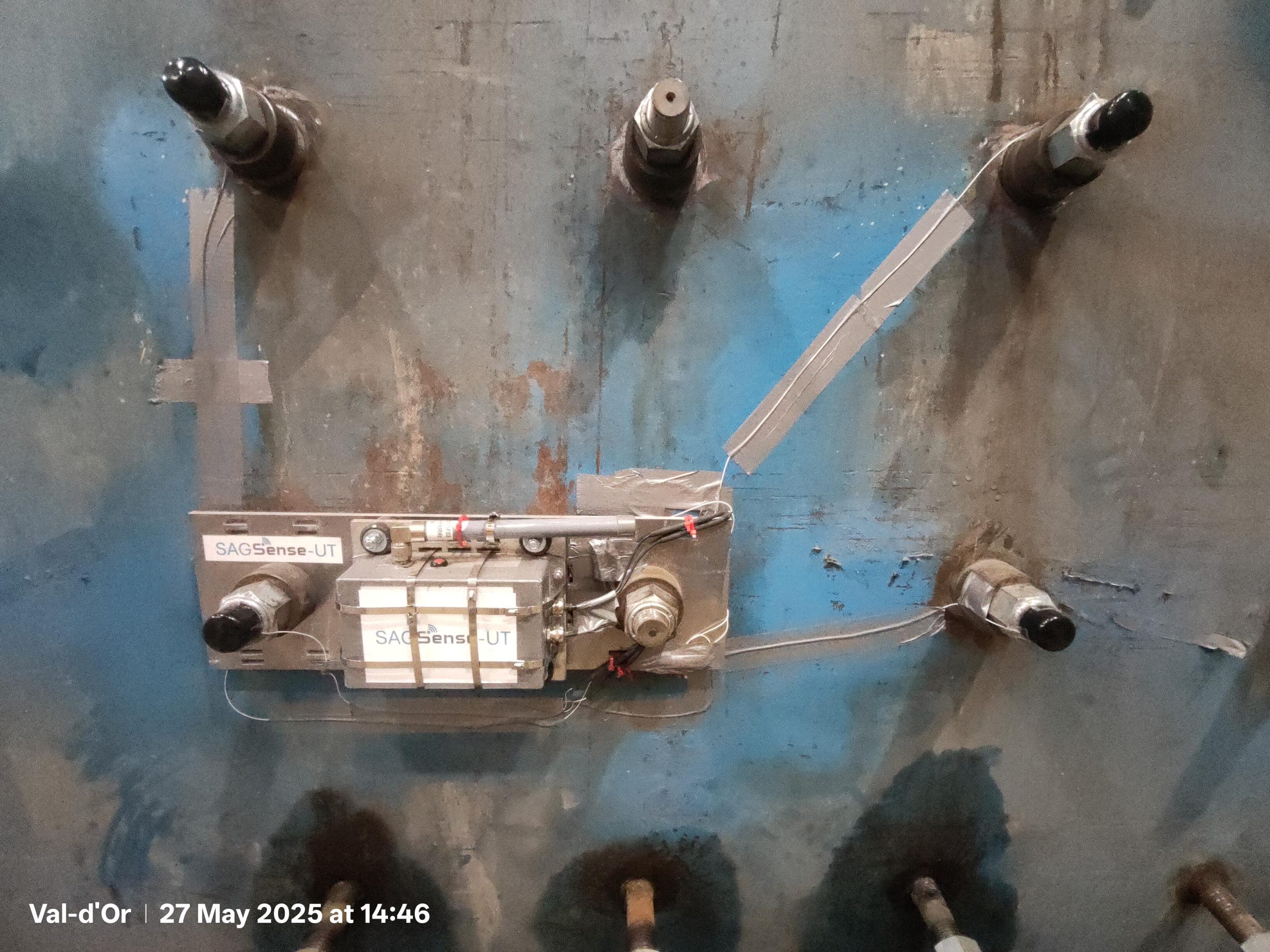

Developed by Linersense Inc., SAGSENSE-UT® is a wireless monitoring solution based on ultrasonic sensors, specifically engineered to operate on rotating equipment such as SAG mills.

The technology enables operators to:

Measure liner wear in real time

Dynamically assess component condition using reliable field data

Optimize maintenance planning

Reduce unplanned downtime

Extend component service life

Lower annual costs associated with SAG mill operation and maintenance

SAGSENSE-UT® aligns fully with Mining 4.0, embedding operational intelligence directly into physical assets.

Quebec’s mining industry is undergoing a major transformation. In 2022, mining investments in Quebec reached $4.76 billion, representing a 10.9% increase year over year (Institut de la statistique du Québec). This growth is accompanied by rapid adoption of IoT, automation, and predictive maintenance technologies.

In this context, intelligent comminution technologies directly address two key priorities:

Improving productivity by reducing unplanned downtime and optimizing equipment lifespan

Enhancing sustainability by limiting production losses, environmental risks, and energy inefficiencies

As early as 2013, a WSP study commissioned by MISA identified SAG mill liner wear measurement as a major issue for mining companies in Abitibi. SAGSENSE-UT® is therefore grounded in long-standing operational realities and continuous improvement needs.

By integrating SAGSENSE-UT® sensors into SAG mills, mining operators can transition from a reactive to a predictive maintenance approach, with continuous access to data on:

Actual liner condition

Impact frequency and load intensity

Operational anomalies

Wear progression over time

This monitoring capability helps to:

Reduce mechanical surprises

Schedule maintenance at the right time

Avoid costly shutdowns

Improve intervention safety

Designed by a Quebec-based company born from the alliance of two experienced industrial players—Labcan and Techno Vogue—SAGSENSE-UT® reflects a shared vision: delivering robust, easy-to-deploy, and high-value tools adapted to real mining conditions.

Its modular, wireless design, specifically developed for SAG mills, makes it an accessible technology lever for operators looking to modernize maintenance practices without disrupting existing operations.

By supporting projects such as SAGSENSE-UT® through the Vortex Journey – IoT Chapter, MISA Group acts as a catalyst for applied mining innovation, highlighting solutions that directly address real operational challenges faced by Quebec mining companies.

This project exemplifies:

Sensor integration in intelligent maintenance

Data-driven optimization of critical assets

Valorization of Quebec industrial expertise

Tangible improvements in operational performance

In an industry where every unplanned shutdown can cost tens of thousands of dollars per hour, the ability to anticipate equipment wear becomes a decisive competitive advantage. With SAGSENSE-UT®, Linersense Inc. delivers an effective, accessible, and highly relevant solution to support safer, more reliable, and more productive mining operations.

– Until February 20, Corem and…

A reflection presented by MISA…